Grooving technology

In a simplest way, it is:

Apply the V-grooving (or V-cutting) method on the metal sheet first, and then bend the grooved metal sheet into various angles and shapes by pressing the brake with a general mold or a special mold.

Advantages of metal V grooving method:

- Small bend radius

- Reduce the error when bending

- Reduce force when concussion

- The quality of the product after being crushed reaches a high aesthetic level

Because of the above advantages, the V-grooving or V-folding method is used to create decorative products in hotels, restaurants, shopping malls, airports….

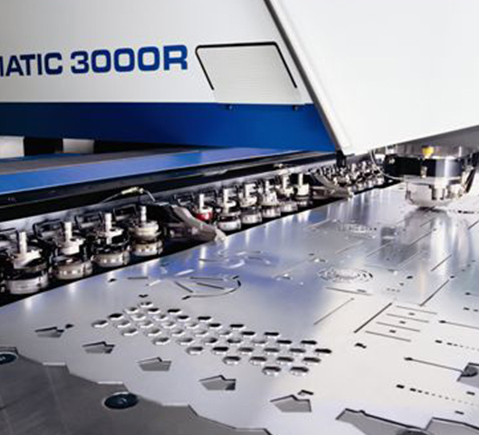

The process of grooving V

The metal sheet is fixed and the metal material on the moving track is cut using the mechanical movement of the V-groove blade to form a process V-groove.

The size of the bend angle is related to the depth of the V-groove. The smaller the bend angle, the larger the depth of the V-groove to be grooved

The length of metal plate for V-grooving is: 2500mm, 3200mm, 4000mm, 5000mm, 6000mm

The processing width of sheet metal is mainly: 1250mm, 1500mm, 2200mm, 2400mm.

Grooving Materials: Stainless Steel Sheet, Aluminum Sheet, Copper Plate, Corrugated Sheet

Tiếng Việt

Tiếng Việt 日本語

日本語