HHT Corporation was established in 2014 and developed rapidly through import, export and trading of Aluminum Alloy. Continuing to expand the market, HHT Metals was born with sheet metal processing services, which are applied in many fields: construction, marine, industrial…

| HHT Aluminum: provide aluminum alloy | HHT Metals: Sheet metal CNC machining |

|

|

HHT Aluminum: specializes in import and distribute aluminum coil and plate

HHT Aluminum: is the leading unit in Vietnam specializing in importing and distributing Aluminum Alloy Sheet, Aluminum Coil, Aluminum Ribbed Anti-Slip… with Aluminum grades such as A1050, A3003, A5052, A5083, A6061, A7075… Products At HHT Aluminum is imported directly from India, Korea, Japan, EU/G7 and provides a variety of types and sizes, supplying to all provinces in the country.

- Advantages of HHT Corporation:

- Directly imported from India, Korea, Japan, EU/G7

- Supplying quality and quantity Aluminum sheet – various sizes and types

- Wholesale & Retail Supply

- Goods with full CO, CQ

- Products meet ASTM, EN, JIN standards..

- Competitive price – professional service.

HHT Metals: Metal CNC processing according to requirements

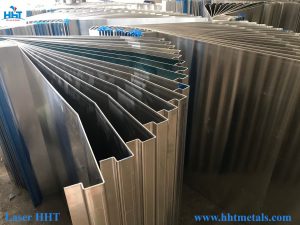

Are you working in the construction, industrial, marine or oil and gas sectors, the use of Aluminum sheet brings more benefits than other materials (Iron, Copper …) because it is light and flexible. We process and fabricate aluminum sheet metal according to the technical requirements and quantity from the customer. The aluminum sheet processing stages of HHT Metals include:

- Metal Laser Cutting

- CNC Punching

- Grooving

- CNC Folding Press

- Laser, Tig, Mig . Welding

- Painting, finished products

We start by selecting the aluminum sheet material that is suitable for the product’s physical properties then cut or punch the aluminum sheet material with different CNC machines, and then shape it as you want. The details can be connected by welding or using adhesives or by bolts, screws or rive… Then finish the product by electrostatic painting.

Compared to machining made with other materials, aluminum does not corrode over time because aluminum sheet has very good corrosion resistance. It is perfect for use in high temperature or chemically resistant environments. The most significant benefit of machining aluminum sheet over stainless steel plate, steel or other metal is the different weight between materials.

Aluminum sheets are often used for processing and manufacturing.

- Grade A1050-H14 . aluminum

- Grade A3003-H14 . aluminum

- Grade A5052-H32 . aluminum

- Grade A6061-T6 . aluminum

|

|

|

|

|

|

Tiếng Việt

Tiếng Việt